continuous 3D printer

continuous 3D printer

850 x 500 x ∞ mm, bis zu 300 dpi | VXC800

Vnation JSC

-

Other characteristics:

continuous

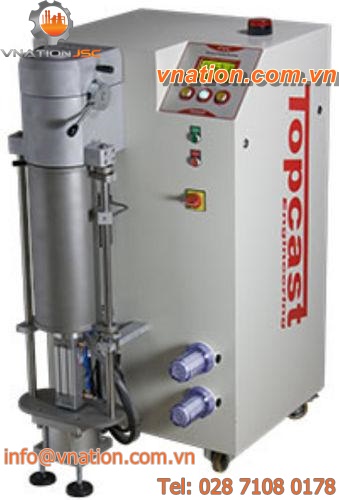

The VXC800 is the world's first continuously operating 3D printer. The proven layering process has been significantly enhanced. Instead of using a static building platform, the printing process takes place on a conveyor belt. The recoater, which is used to apply the particulate material, and the print head work at an inclined angle instead of horizontally. This ensures that the printed molded parts cycle continuously. They only need to be freed of unprinted particulate material and removed from the conveyor belt after the cycle is completed. The precise interplay between the recoater, print head and conveyor belt enables the molded parts to be built and unpacked simultaneously without interruptions.

The molded parts can have almost any length, due to the continuous printing process. The build space measures 850 x 500 mm in width and height. The VXC800's print head system can achieve a resolution of up to 300 dpi. A layer applied in one cycle is 300 ?m thick.

High-tech engineered in Germany:

Like all of voxeljet's 3D printing systems, the VXC800 is ideal for producing complex components and prototypes fully automatically and without tools. Thanks to the continuous printing process and high build speed, these printers are the right choice for fast and flexible production under industrial conditions. Their rugged design makes them durable and suitable for continuous operation. The machines are developed in Germany and manufactured with a high degree of vertical integration.